Introduction

Molded thermoset elastomers do not lend themselves to levels of tolerancing seen in machined metals or even in molded thermoplastics. Many factors involved in the manufacturing of molded rubber products affect tolerances.

Shrinkage

Shrinkage is defined as the difference between the corresponding linear dimensions of the mold and of the molded part, with both measurements made at room temperature. Shrinkage is affected by variables such as the compound material itself, cure time, temperature, pressure, over-molded inserts, and post cure.

All rubber materials exhibit some amount of shrinkage after molding, when the part cools. The manufacturer must determine the amount of shrinkage for the selected compound and then incorporate this allowance into the mold cavity size. Even though the mold is built anticipating shrinkage, there remains an inherent variability that must be covered by adequate dimensional tolerance.

Shrinkage of rubber is a volume effect. Complex shapes in the molded product, or the presence of inserts, may restrict the lineal shrinkage in one direction but increase it in another direction. The goal of the rubber manufacturer is to minimize these variables, but they cannot be eliminated entirely.

Mold Design

With any type of mold, the mold builder must have some tolerance, and therefore, each cavity will have a bit of variance from the others. Dimensional tolerances on the product must include allowances for this fact.

The accuracy of the mold register must also be considered. Mold register involves matching of the various plates of the mold that form the mold cavity. Register is controlled by dowel pins and bushings, self-registering cavities, or parting line locks.

Molds can be designed and built to varying degrees of precision, but these levels do not have the same cost. For molds requiring high precision in dimensions and register, the design work and machining must be more precise, and therefore the cost of the molds will be greater than those with commercial requirements.

Compound & Process Variation

Batch-to-batch variation in the rubber compound itself is due to the accepted variation in each of its many ingredients. This compounded variation can require the processor to alter molding parameters in order to achieve optimum part quality. For example, the technician may need to make controlled adjustments to mold temperature or injection speed for a given batch of rubber, and such a change can result in an effect on part dimensions.

Trim and Finish

The objectives of trimming and finishing operations are to remove rubber material, such as flash, that is not a part of the finished product. Often this is possible without affecting product dimensions, but in other instances, some material is removed from the part itself. If the required design tolerances cannot be achieved as-molded, the manufacturer may perform post-molding finishing operations, such as grinding, at additional cost.

Inserts

Most insert materials (metal, plastic, etc.) have their own standard tolerances. When designing inserts for molding to rubber, several additional factors must be considered, such as: fit in the mold cavities; location of the inserts with respect to other dimensions; proper hole spacing to match with mold pins; and positioning inserts at room temperature into a heated mold. In these matters, the rubber manufacturer can be of service in advising on design features and required tolerances.

When rubber is chemically bonded to an insert, it is restricted from shrinkage at the glue line, which causes areas of the part farther away to shrink more. Such an outcome results in surfaces that are not square or parallel as designed. The engineers here at Molded Dimensions Group can advise how to compensate for these effects.

As Designed

As Molded

Distortion

Because rubber is a flexible material, its shape can be affected by temperature. Distortion can occur when the part is removed from the mold, when it is packed for shipment, or when it sits in bulk packaging in a truck or on a customer’s shelf. This distortion makes it difficult to measure the parts properly. Some of the distortion can be minimized by storing the part as unstressed as possible at room temperature.

Dimension Terminology

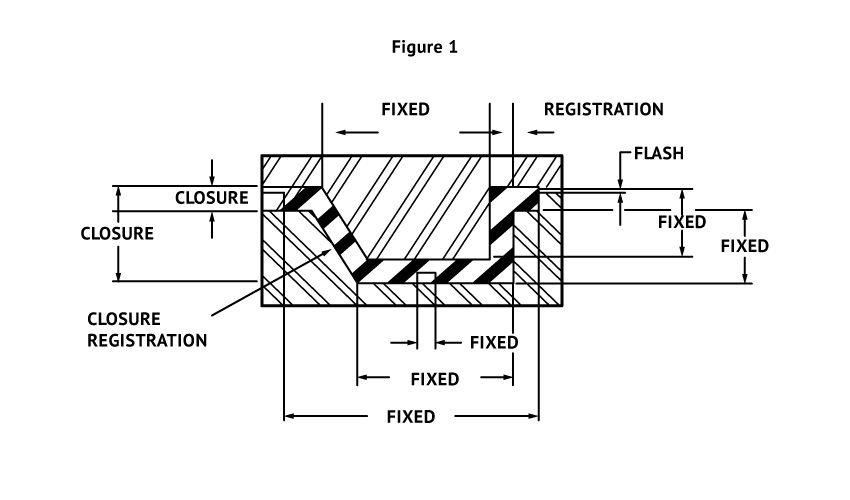

Figure 1 provides common terminology for use in discussing dimensions of molded rubber products and for distinguishing various tolerance groupings:

- Fixed Dimension: Dimension not affected by flash thickness variation (formed in same plate)

- Registration Dimension: Dimension affected by the matching of the various plates of the mold that form the mold cavity.

- Closure Dimension: Dimension affected by flash thickness variation (formed by more than one plate; i.e., crosses parting line)

- In addition to shrinkage, mold design, process variation, trim and finish, and the presence of inserts, other factors affecting closure dimension include: flow characteristics of the raw stock, weight, shape of preform, and molding process.

- Although closure dimension is affected by flash thickness variation, it is not necessarily related to basic flash thickness. For instance, if a manufacturer plans to machine or die trim a product, the mold will have a built-in flash, which will be thicker than if hand de-flashing or cryogenic de-flashing were to be employed. Thus, products purchased from two sources could have different basic flash thickness at the parting line and yet meet drawing dimensions.

There is usually a logical place for the mold designer to locate the parting line so as to avoid working surfaces while also optimizing mold cavity filling, dimensional control, and ease of part removal. If the product design limits this location, an alternate mold construction will be required, which may affect the tolerance control on the product, and, in some cases, increase the cost of the mold.

There are four levels of dimensional tolerances that are used for molded products. The level selected should be based upon the determined need using the following guidelines.

There are four levels of dimensional tolerances that are used for molded products. The level selected should be based upon the determined need using the following guidelines.

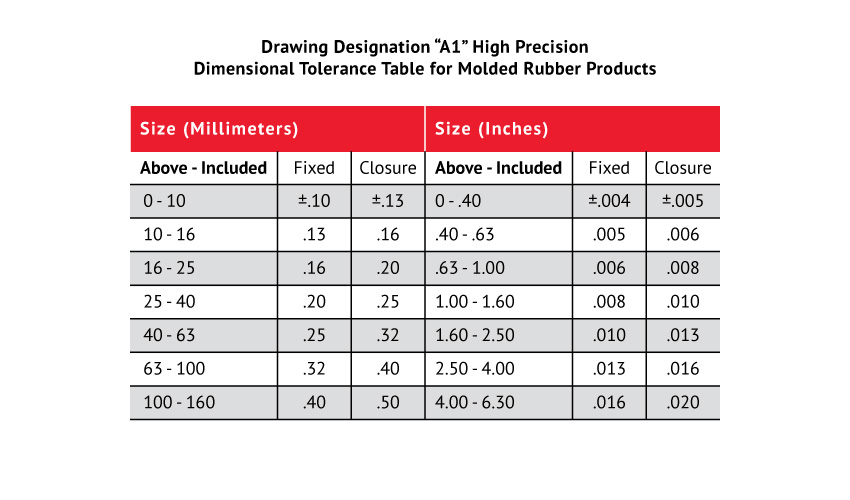

- “A1” High Precision is the tightest tolerance classification and indicates a high-precision rubber product. Such products require expensive molds, fewer cavities per mold, costly in-process controls, and inspection procedures. The exact method of measurement should be agreed upon between rubber manufacturer and customer, as even slight errors in measurement may be large in relation to the tolerance. Some materials, particularly those requiring post-curing, do not lend themselves to “A1” tolerances.

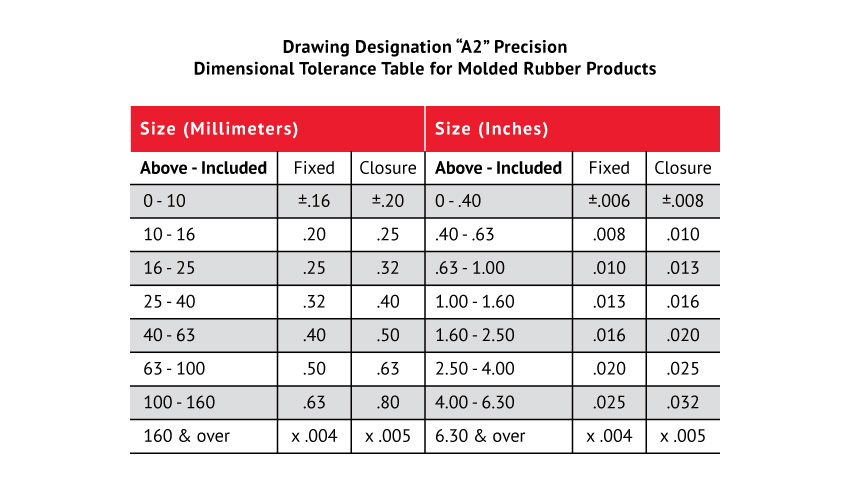

- “A2” Precision tolerances indicate a product accuracy achieved through molds that are precision-machined and kept in good repair. While measurement methods may be simpler than with an “A1” classification, careful inspection will usually be required.

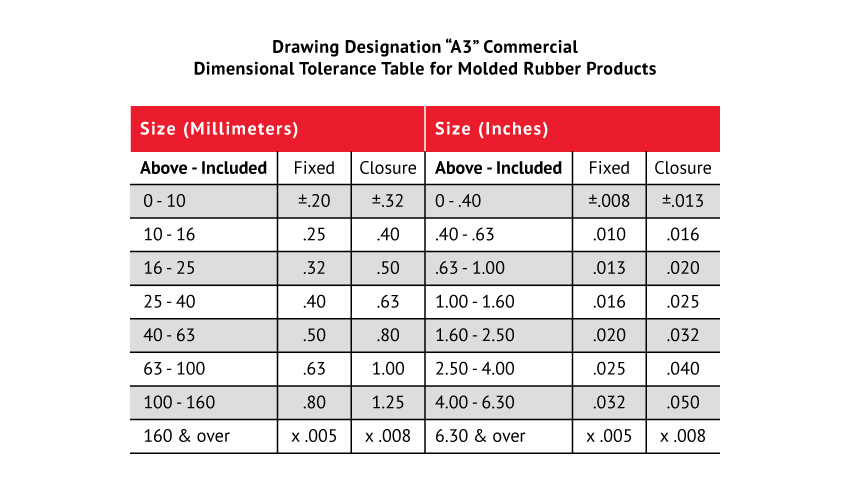

- “A3” Commercial tolerances indicate a “commercial” product and are normally used for most products.

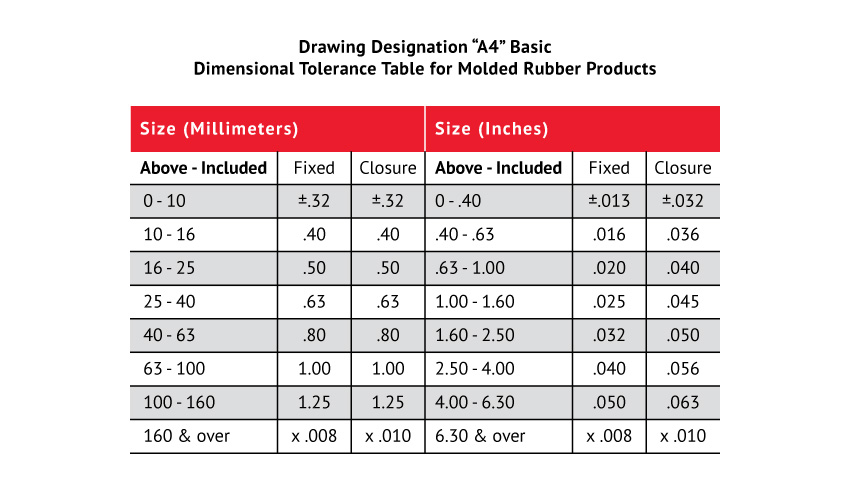

- “A4” Basic tolerances apply to products where some dimensional control is required, but secondary to cost.

When applying tolerances, the following rules should be kept in mind.

- Fixed dimension tolerances apply individually to each fixed dimension by its own size.

- Closure dimension tolerances are determined by the largest closure dimension, and then this single tolerance is used for all other closure dimensions.

- Fixed and closure dimensions for a given table do not necessarily go together and can be split between tables.

- Tolerances not shown on product drawings should be determined in consultation with the rubber manufacturer.

- Care should be taken in applying standard tolerances to products having wide sectional variations.

Dimensional inspection is performed on part surfaces away from gates. Gate vestige standing proud is not included in these tolerance tables, and it may need to be trimmed at additional cost if unacceptable for product performance.

Measurement of Dimensions

Measurement of Dimensions

Conditioning of Parts

Measurements of dimensions shall be made on parts conditioned at least 24 hours after the molding operation. Measurements shall be completed within 60 days after shipment, or before the part is put into use, whichever is the shorter time. Care shall be taken to ensure that the parts are not subjected to adverse storage conditions.

In the case of referee measurement, particularly on “A1” tolerances or for materials known to be sensitive to variations in temperature or relative humidity, the parts in question should be conditioned for a minimum of 24 hours at 23° ± 2° C (73.4° ± 3.6° F) and at 50% ± 5% relative humidity.

Methods of Measurements

Depending upon the characteristics of the dimension to be measured, one or more of the following methods of measurement may be used:

- A non-contact optical measuring device

- Fixed gauges appropriate to the dimension being measured

- 3D scanning of the physical part compared to the design file

- Other methods agreed on by the customer and rubber manufacturer

Under no circumstances should pliable parts be distorted during measurement, as is often the case when using calipers or a Coordinate Measuring Machine (CMM). On dimensions that are difficult to measure or that have unusually close tolerances, the exact method of measurement should be agreed upon in advance of mold construction by the customer and rubber manufacturer.

Special Considerations for Tolerancing of Urethane Parts

Most of the aforementioned considerations are applicable to urethane parts cured under pressure in closed molds. Parts cast in an open mold will have an exposed part surface, or a riser, for pouring urethane into the cavity. Tolerances of this surface are affected by fill volume and meniscus effects, in addition to other factors such as material shrinkage, mold design, etc. The urethane molder can advise tolerancing for open cast surfaces on a part-by-part basis. If the required design tolerances cannot be achieved as-molded, post-molding finishing operations, such as grinding, may be performed at additional cost.

Access more articles in our Rubber Knowledge Center and our Urethane Knowledge Center.