Tear resistance is a complex result of other basic properties, such as modulus and tensile strength. Many laboratory methods have been devised to measure this property. While the tests used to measure the tear resistance of elastomers are useful for laboratory comparisons, correlation between test results and service performance is often quite difficult. The various tear tests produce different results when used with urethane rubbers.

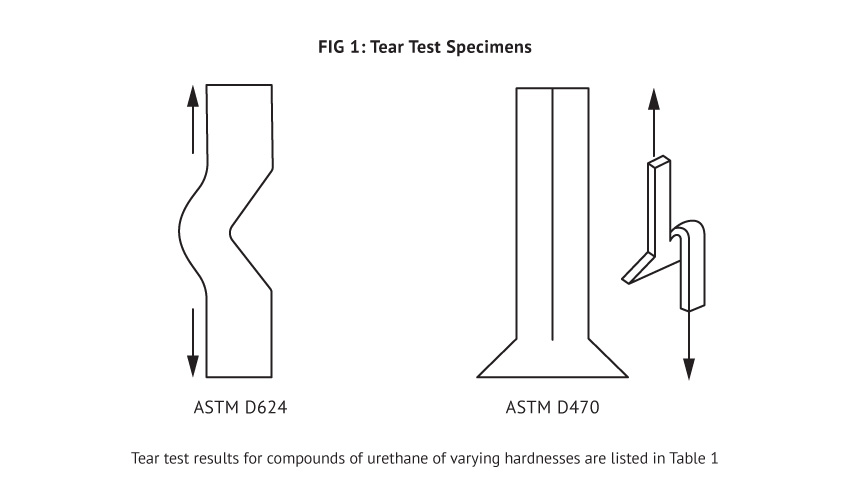

The following tear tests for urethane have been compared: ASTM D-470 Split Tear

and ASTM D624 Die C. The ASTM D-470 split tear test is least dependent on tensile strength and gives the most realistic evaluation of the tear strength of urethane. Specimens used in each test are shown in Figure 1.

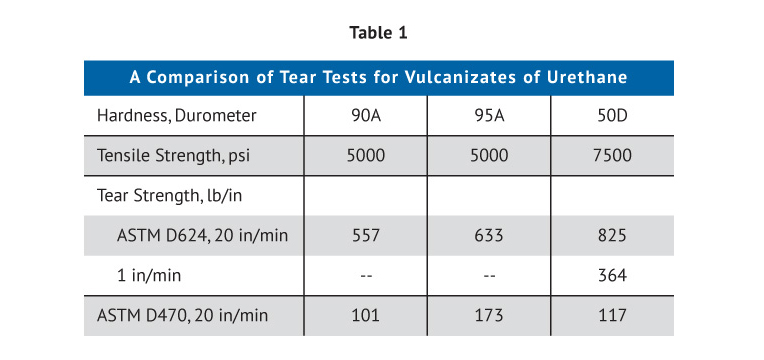

Tear test results for compounds of urethane of varying hardnesses are listed in Table 1.

Tear test results for compounds of urethane of varying hardnesses are listed in Table 1.

Results are computed in terms of force required, per inch thickness, to tear the specimen. For example, if a load of 40 pounds is necessary to tear a specimen 0.07 inches in thickness, the tear resistance would be 40/0.070 = 572 lb/in.

Results are computed in terms of force required, per inch thickness, to tear the specimen. For example, if a load of 40 pounds is necessary to tear a specimen 0.07 inches in thickness, the tear resistance would be 40/0.070 = 572 lb/in.

ASTM D624 (Die C) tear values increase with increasing urethane hardness. The absolute values obtained with this test are high, since the test depends, to a large extent, on tensile factors. For some of the harder compounds, slowing the head speed from 20 inches per minute to one inch per minute permits the sample to relax during the test; this reduces the effect of tensile strength, resulting in lower values. For example, 50D urethane pulled at 20 inches per minute gives a tear strength that is much greater than a tear strength obtained by pulling the same compound at one inch per minute.

ASTM D-470 test values increase with increasing hardness for 90A urethane and 95A urethane, but are lower for 50D urethane, even though these compounds are harder. Absolute values from this test are the lowest of all the tests studied. The split tear test tends to eliminate tensile factors and thus give a more realistic evaluation of cut growth resistance. This test appears to be the best available measure of the tear resistance of urethane.

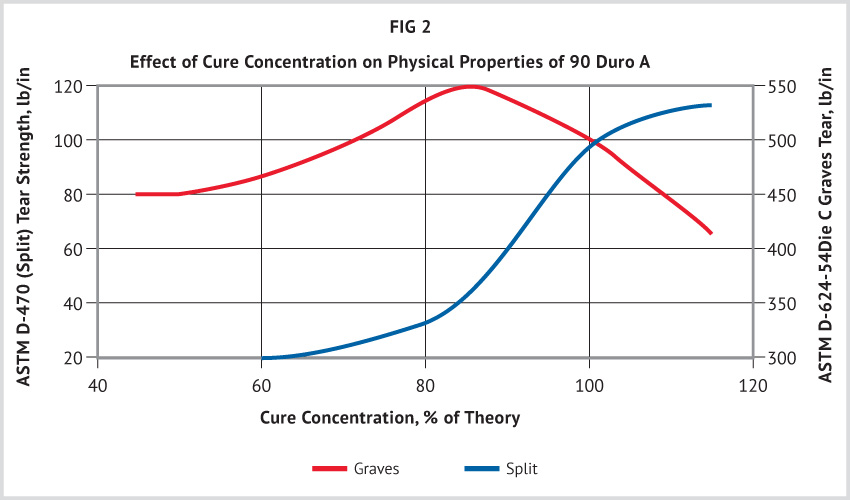

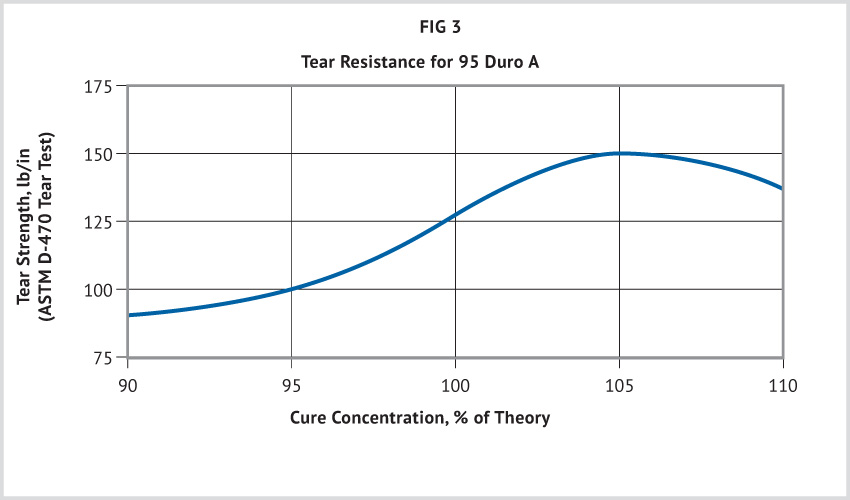

Tear strength of 90A urethane and 95A urethane can be enhanced by the use of cure levels at 100 to 110% of theory. This improvement is illustrated in Figures 2 and 3.

The increase in tear strength is attributed to a more linear polymer chain with less crosslinking.

Access more articles in our Urethane Knowledge Center.