When new to the injection molding industry, many people inquire as to why injection molds have a high cost. Often, knowledge of plastic molded parts only comes in the form of low-cost storage bins, toys, or even food containers. But the creation of complex, custom injection molds is a lengthy process—taking months, or even a year or more, to bring a part from concept to reality.

Plastic product design has many unique challenges and requirements. Design considerations need to always consider the “moldability” of a part, to help reduce the cost of manufacturing and increase the product’s chance for success. Through development simulations, prototype testing, and judicious material selections, a project can be effectively modeled.

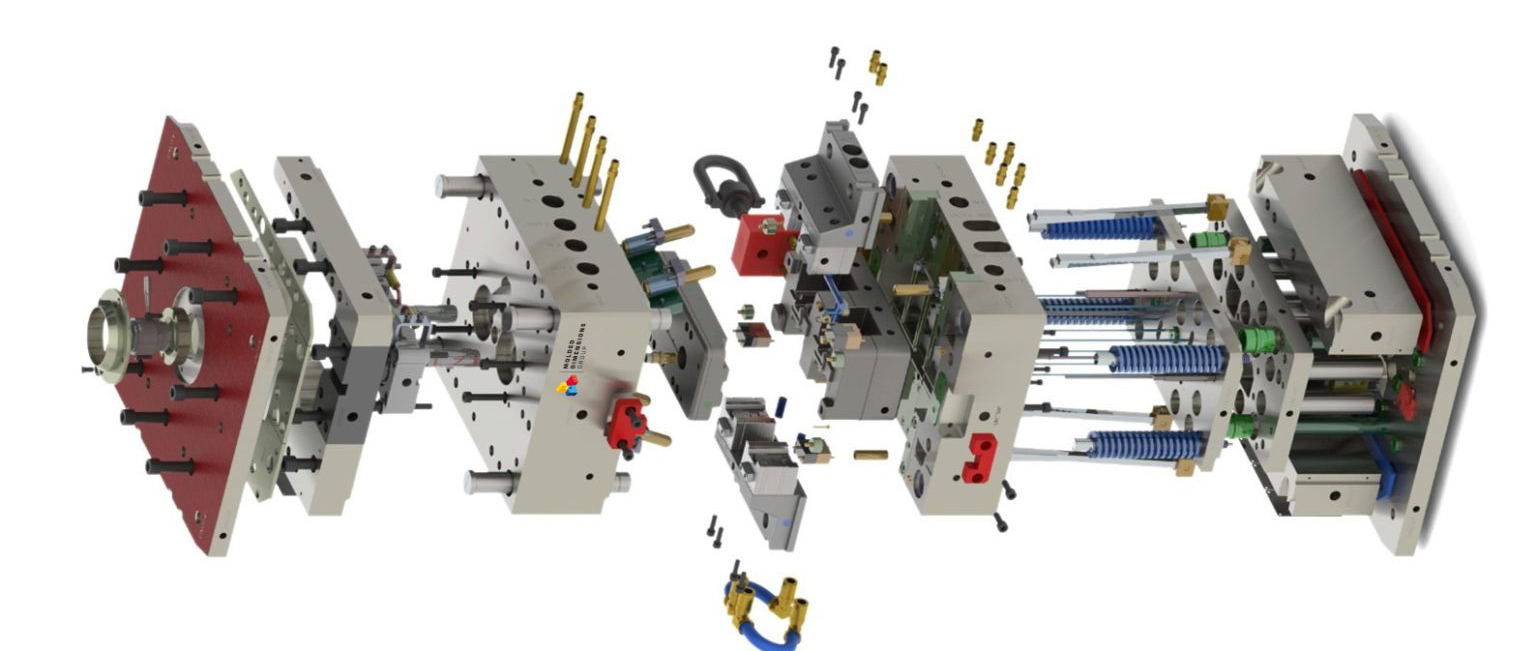

In the next step of mold development, the program at Molded Dimensions Group really shines. Physical mold design is a specialty, and expertise is required to meet the demands of multifaceted injection molding. To allow us to properly mold a high-quality precision product, we have invested in skilled labor, specialized tooling steels, mold bases, and other unique industry components.

The molding process is truly a science. The polymers are melted at specific temperatures with very specialized equipment and subsequently injected at extreme pressures. The molds need to be built to withstand these pressures, as well as cool the resin evenly and quickly.

The structure and components of the mold need hundreds of hours of specialized toolmaking: this includes the machining, grinding, polishing, and fitting mechanisms. The materials, specialized engineering, and toolmaking labor and equipment all contribute to the costs of a mold.

Partnering with Molded Dimensions Group early in the development of a mold helps optimize costs and makes your ‘tooling dollar’ go further. Contact us today to discuss costs for your next project. And find more useful articles like this one in our Plastic Knowledge Center.