There are two types of abrasion: sliding and impingement. Sliding is the passing of an adjacent surface across the elastomer surface. Impingement is wearing of the elastomer, exemplified by sand particles hitting the surface. Most wear in actual service occurs as a combination of both sliding and impingement abrasion.

When sliding, localized friction forces can impose high energy levels on the elastomer. Abrasion and wear take place when the elastomer cannot withstand these forces.

Impingement by particles occurs in applications such as chutes, rebound plates, and sandblast hoses. Elastomers can yield easily and distribute stresses imposed by particle impingement. A sandblast test shows that with a 90-degree impingement angle, soft resilient rubber is more abrasion-resistant than is steel or cast iron. However, not just any elastomer can be used. Under this same condition, a tough tire tread will wear out more rapidly than a soft elastomer. The angle of particle impingement has a significant effect on which material should be used. As the angle decreases below 90 degrees, the superiority of elastomers over metals declines and eventually disappears.

Laboratory abrasion tests are difficult to correlate with end-use applications. Measurement of properties can be helpful in material selection, but such a test does not compare to rates in actual service, which can be thousands of times greater with regard to velocities and temperatures.

There are at least 25 laboratory abrasion test devices, an indication that this type of test is difficult to correlate with service performance. The most widely recognized test device in the rubber industry is the National Bureau of Standards (NBS) Abrader, a slinging type of abrader. The NBS Abrader uses a constant velocity, under a fixed load, with a specified abrasive grit.

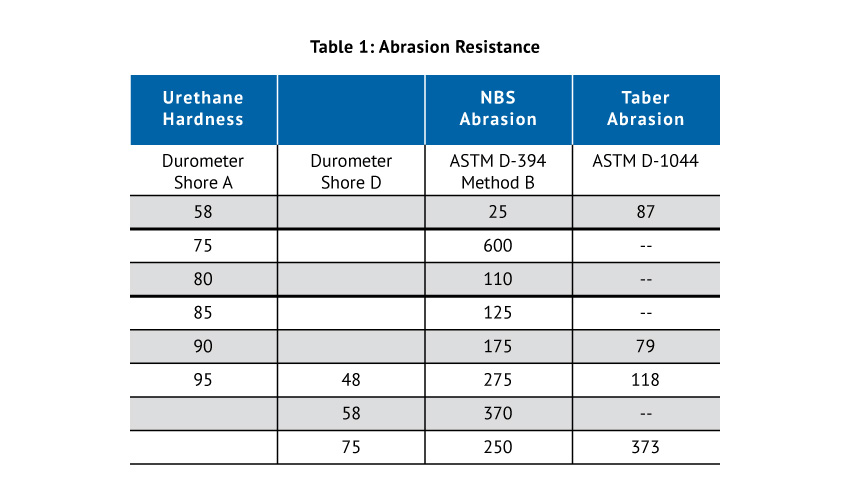

In general, the abrasion resistance of cast urethane is superior to rubber. Urethane’s abrasion resistance, as measured on two laboratory tests—the NBS test and the Taber Abrader—is shown in Table 1.

Note that these two tests give different values. However, the differences in performance of urethane vulcanizates can be explained. The NBS test simulates a very harsh service. In this case, the hardest vulcanizates hold up best. The Taber test is much less severe, so softer compounds perform better than harder ones because they are more resilient and “give” under load.

Note that these two tests give different values. However, the differences in performance of urethane vulcanizates can be explained. The NBS test simulates a very harsh service. In this case, the hardest vulcanizates hold up best. The Taber test is much less severe, so softer compounds perform better than harder ones because they are more resilient and “give” under load.

For the NBS test, the resistance to sliding abrasion increases with increasing hardness. The unusually high NBS Index for the 75A durometer vulcanizate is likely due to lubrication of the abrasive wheel by the plasticizer used in the compound. As the hardness of urethane increases, NBS values increase for non-plasticized compounds.

In spite of the difficulties in obtaining meaningful laboratory abrasion test values, urethane is considered to have excellent sliding abrasion resistance and has performed well in many applications for which wear is a problem. Urethane has outworn conventional rubber and plastics, often by a factor of as much as 8 to 1.

Access more articles in our Rubber Knowledge Center and our Urethane Knowledge Center.