All designers need to pick a material to make their parts, but matching an application to a specific plastic can be a daunting task. The following questions provide a path toward narrowing the possibilities, by optimizing performance, cost, and longevity. The selection process entails a macro evaluation of the possible polymers, such as polycarbonate, ABS, nylon, propylene, and more. While several plastics may meet the requirements, specific types and grades need to be chosen as well—and this is where economics can also make a huge impact.

- What are the physical property requirements?

- What are loads on the part?

- What type of loads?

- How long are the loads applied?

- What is the size of the part?

- How thick are the part walls?

- What is the planned service life of the part?

- Is the part going to see abrasion or wear?

- In what environment will the part live?

- Will the part be exposed to light? Indoors or outdoors?

- In what temperatures will the part live, and for how long?

- Will the part be impacted at low temperatures?

- Will dimensional changes due to temperature cause problems?

- To what substances will the part be exposed?

- Will the part be cleaned? What type of cleaners or solvents?

- Will the part be painted or decorated? What type of paint, ink, or dye?

- Will the part be introduced to water, steam, or moisture?

- What chemicals will be in contact with the part?

- Other concerns

- Will the part require any regulatory requirements? Examples include FDA, aerospace, automotive, UL, NSF, etc.

- Is there a flame retardant rating required?

- Is there a specific color needed?

- Is the part clear or transparent?

- Is EMI shielding required?

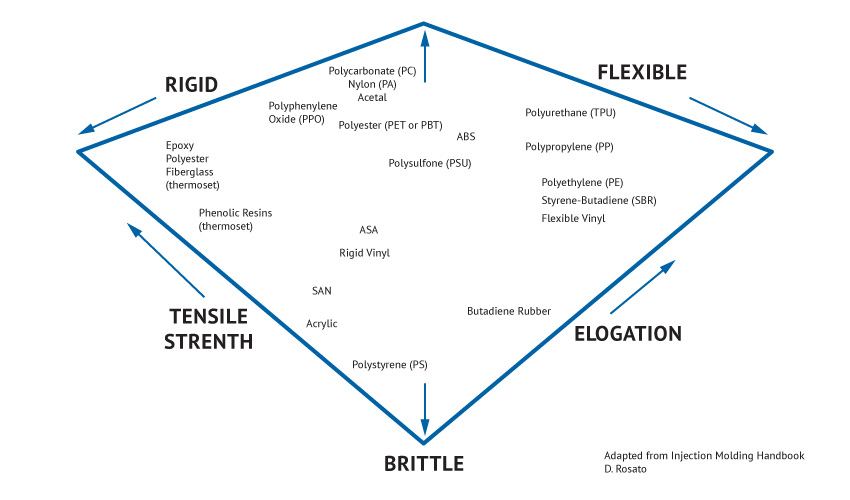

To help identify some material options, the chart included here shows a range of properties in relation to various plastics. This chart does not include a complete list of all plastics, but it does provide a general range of choices. Defining the requirements of the part will help in narrowing down the options. And learning more about existing solutions, used by previous designs, can assist too.

Once a plastic type, or types, have been identified, testing is recommended—either through prototypes, Finite Element Analysis (FEA), or other techniques—to identify a specific grade of resin. Besides contrasting physical properties, each type of plastic may also differ in manufacturer and in its additives for improved processing.

These characteristics can impact the project’s economic questions:

-

- Is the material available in reasonable quantities for this project?

- What is the minimum order quantity for this resin?

- Is there a similar resin available with better pricing or availability?

- Is this a current resin utilized on another part being molded?

As an example: plastics come in a range of densities, and they are priced based on weight. Thus, a lower-density resin would require less material by weight than a higher-density resin—which could mean a significant cost-per-part increase or decrease, depending on the scenario.

Selecting the best material for an injection molded part is a complex decision, but the experts at Molded Dimensions Group would love to assist. Please reach out to our team to learn more!

Access more articles in our Plastic Knowledge Center.