We take pride in designing the best possible polyurethanes the industry has to offer, and that is due to the strict guidelines and standards we set for ourselves.

Sharp Edges

Sharp edges or corners, externally or within the polyurethane part, should be avoided, particularly where the polyurethane is stressed.

Polyurethane-to-Metal Bonding

The generous use of fillets or overhangs serves to distribute stress over a broader area, thus improving the bond and increasing the useful life of the part.

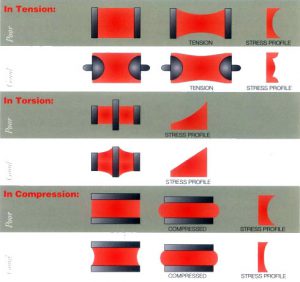

Equalization of Stress

Proper design tends to equalize stress distribution.

Summary

When designing polyurethanes for dynamic applications, avoid:

-

Sharp corners at edges of bonded areas

-

Sharp angles in the polyurethane which tend to focus stresses

-

Sharp lips or edges which would cut or magnify stress concentration

-

Complicated parts which, in addition to requiring expensive molds, have many points of stress concentration

- Designs which prevent natural shaping of the polyurethane when under a load