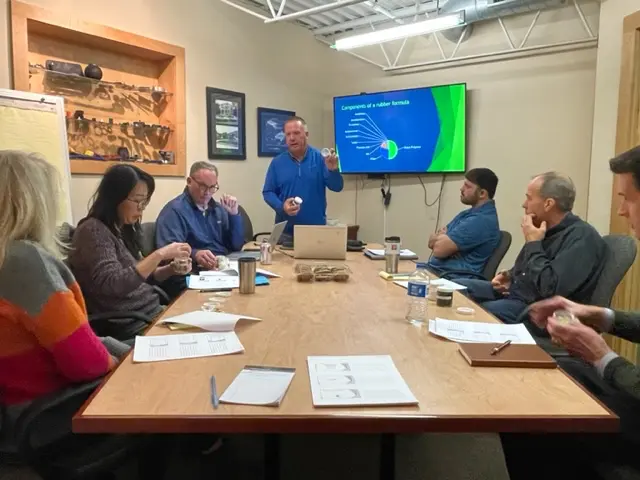

Every once in a while, Chemist Tony Lukas steps away from his office and heads to a conference room where he teaches a two-hour Rubber and Urethane Materials Course for onsite and remote employees of Molded Dimensions Group.

“The class is a general overview of rubber and urethane materials and our processing methods,” says Tony. “Before we start, I always tell my students I hope they can get a couple of nuggets that apply to their job or help explain something they don’t understand.”

Eight people took part in the December 2022 session, which included a supply chain manager, customer service rep, sales, HR, engineers, a foreign distribution buyer and CEO Brian Sprinkman. Four people were taking the course for a second time. Tony admits the course information is a lot to initially absorb and then apply to an employee’s work responsibilities.

“This class was originally developed for all levels of the organization, both to give some color to the work that we do and to create more basic knowledge of our processes. It is helpful to give the reasons for the things we do and have people understand good manufacturing practices.”

Given the employment history of attendees — anywhere from a few months on the job to more than 20 years of service — Tony aptly related the classwork examples to specific requirements in manufacturing, including sampling processes, customer returns, and more.

Tony says customers of the Molded Dimensions Group are also deepening their knowledge of rubber and urethane. One of the sales reps in his class requested a tailored version of the course so he could host a lunch-and-learn with clients.

“It’s fantastic having a chemist on staff who can educate not only our employees, but also our customers, who may need training,” says Bobby Desai, Vice President of Sales & Marketing. “We can be an extension of their technical team and a resource for our valued partners.”